Ten years of a sword

In 2007, Jimei began to recruit excellent soldering iron head manufacturing craftsmanship across the country, aiming to solve the problem that the traditional soldering iron head is easy to wear.

In August 2017, Jimei BEE motor dedicated long-life soldering iron head was born.

In ten years, we have exchanged tens of thousands of times with domestic and foreign counterparts.

In ten years, we have experimented with thousands of material combinations.

In the past ten years, we have solved one problem after another.

For ten years as a day, Shali panned for gold.

■ With higher efficiency and longer life, how does the Jimei BEE motor soldering iron tip work?

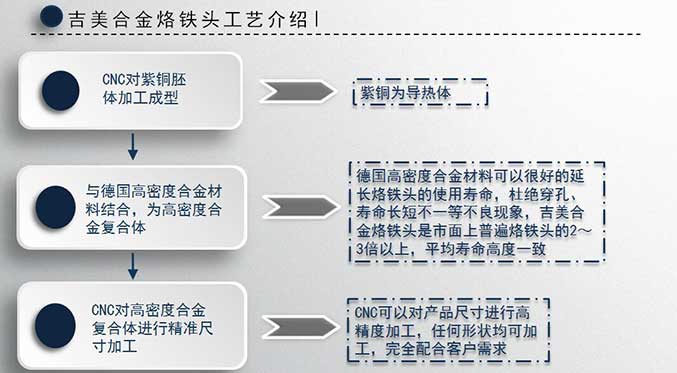

German craftsmanship, elaborate production, completely solve the problem that the traditional motor soldering iron head is not wear-resistant and frequently replaced.

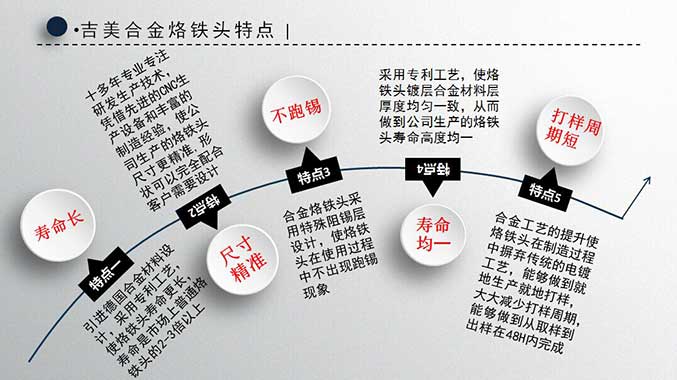

The service life of the special iron head for wear-resistant motors produced by our company is more than twice that of ordinary soldering iron heads. Special super-hard wear-resistant alloy materials are used. The production process uses the company's patented technology. Grinding capacity, life expectancy has doubled.

■ Production efficiency is greatly improved

A customer in Huizhou, who produces motors, originally needed to replace the soldering iron head of the automatic soldering machine twice in one class. After using the company's special soldering iron head for wear-resistant motors, it can achieve the whole course of one class without replacing the soldering iron head, saving two adjustments Time, greatly improve production capacity.