1. Split Desoldering

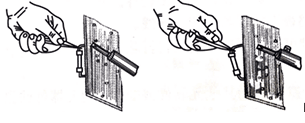

For resistance-capacitance components installed horizontally, the distance between the two soldering points is far away. You can use an electric soldering iron to heat it at a point and pull it out point by point. If the lead is bent, use a soldering iron tip to pry it straight before removing it. Figure 1.

Figure 1 Sub-point desoldering

2.Concentrated folding welding

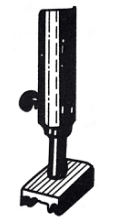

Like transistors and upright mounted resistive-capacitive components, the solder joints are relatively close in distance, and several solder joints can be quickly heated alternately with an electric soldering iron, and then pulled out once the solder melts, as shown in Figure 2. For multi-contact components, such as switches, plugs, integrated circuits, etc., a special soldering iron head can be used to align each soldering point at the same time and remove it with one heating. The shape of the special soldering iron head is shown in Figure 3.

Figure 2 Centralized desoldering

Figure 3 Dedicated soldering iron head

3.Discontinuous heating desoldering method

When desoldering a component with poor heat resistance, in order to avoid damage to the component due to overheating and the component cannot be continuously heated for a long time, the interval heating method should be used for desoldering.