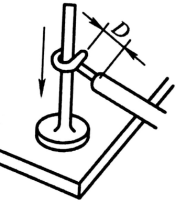

The PCB pin is the terminal used for connecting the wire to the PCB board, as shown in Figure 1.

Figure 1. PCB pin

■ Wire and PCB pin welding steps

(1) Pre-treat the end of the wire.

(2) Cross the pre-treated wires with the PCB pins to make vertical contact, as close as possible to the bottom of the PCB pins, and the wire insulation is about a core diameter away from the terminal.

(3) Use needle-nose pliers to wrap the wire pretreatment end around the PCB pin, as shown in Figure 2 after winding.

Figure 2. How to connect the wires and PCB pins.

(4) For soldering, pay attention to the placement of the electric soldering iron in the direction opposite to the insulation layer of the wire. A small amount of solder is added to the soldering iron tip to facilitate heat transfer. Adding solder wire on the opposite side of the electric soldering iron forms a good soldering. The solder should not be too small. Too little strength is not enough, nor too much, too much is easy to form accumulated solder on the PCB header. Causes bad welding such as virtual welding and connecting feet.

(5) Clean and arrange.

■ Matters needing attention

(1) all temporary welding during testing and debugging shall adopt lap welding method.

(2) if conditions do not permit, the soldering iron and solder wire shall not be placed on either side of the terminal post in the way of up and down.

(3) in all kinds of welding, it is best to use special round tools, such as round nose pliers, to facilitate the welding of wires and terminal posts for the bending of wires after pretreatment. If general nose pliers are used, care should be taken not to scratch or damage the conductor. There should be some clearance between the conductor insulation cover and the terminal post. The length should be the conductor core diameter.

(4) in order to get good welding effect, should add solder on terminal, and to add in the contralateral soldering iron, solder by hot terminal melt and flow to the conductor, the formation of welding, soldering can't use too much, should be paid attention to in order to ensure that, to see the outline of each wire ever apparent dip soldering, and whether the surface gloss.