This article takes the BEE brand welding head produced by Jimei Electronic Equipment as an example to illustrate, often paying attention to the cleaning and maintenance of the welding head, not only greatly increasing the life of the welding head, but also fully exerting the excellent heat transfer performance of the BEE welding head. So, how should the welding head be maintained daily?

■ Try to use low temperature welding:

High temperature will accelerate the oxidation of the welding head, weaken the tin function on the welding head, and reduce the life of the welding head. If the temperature of the welding head exceeds 470 ℃, its oxidation rate is twice that of 380 ℃. As long as enough heat is available for the welding speed (maximum 2 to 3 seconds per weld spot), the temperature should be adjusted as low as possible. The LT welding head has excellent temperature restoring force, and the lower temperature can also be fully welded, which can protect the temperature-sensitive components.

■ Do not apply excessive pressure: When welding:

Do not apply excessive pressure, otherwise the welding head will be damaged and deformed. As long as the welding head fully contacts the solder joint, heat can be transferred. In addition, choosing the right welding head can also help transfer.

■ Always keep the soldering head tinned:

When the welding pen is on the bracket, it must be protected by tin plating. It can also reduce the chance of oxidation of the welding head, making the welding head more durable. After use, new solder should be added after the temperature of the welding head is slightly lowered, so that the tin plating layer has more anti-oxidation effect. If the soldering temperature is higher than 350 ℃, and the work is suspended for more than 1 hour, the soldering head should be cleaned and tinned frequently. Otherwise, the solder on the soldering head will be oxidized, resulting in the phenomenon of not tin. When used as maintenance work, special attention should be paid to the soldering of the welding head. Usually only a small amount of solder can be used, and the welding head should be cleaned frequently. In order to avoid the tin coating on the welding head disappearing quickly, making the welding head difficult to tin, the welding head should be re-tinned frequently.

■ Keep the welding head clean and clean oxide immediately:

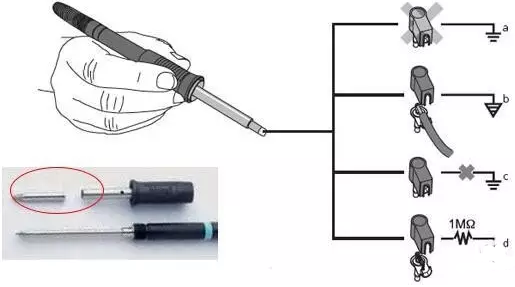

The welding head should be cleaned regularly with a cleaning sponge. After welding, the oxides and carbides derived from the residual flux of the welding head will damage the welding head, cause poor welding, or reduce the heat conduction and tin function of the welding head. When using the soldering station for a long time, the welding head should be disassembled once a week to remove oxides to prevent the welding head from being damaged and reducing the temperature. The cleaning welding head should use the cleaning sponge made by WELLER factory, and add some water (cloth not available). Because of the electroplating, the WELLER welding head must never be filed or ground. The welding head will remove its protective coating and reduce its life. If the dirty welding head needs to be cleaned, WPB1 can be purchased for use.

■ Use low-active flux:

Highly active or highly corrosive flux will accelerate the corrosion of the welding head when heated, so low corrosive flux should be used. When welding, try to use neutral active flux, and avoid excessive use of flux as much as possible. If the welding head is not tinned, use flux and cleaning sponge to clean the surface of the welding head. There is not enough flux in the small-diameter solder wire for cleaning the welding head. For this reason, the larger-diameter solder wire or liquid flux is easy to clean. Remove the soldering head regularly, and use a suitable cleaning agent to remove the flux above. The frequency of cleaning depends on the way and frequency of use. It is recommended to use WELLER welding head protection agent.

■ It is recommended that you apply fresh solder to the welding head during the first heating in order to remove the oxide coated on it.

■ Avoid using anti-seizure solder (except threaded head), otherwise it will affect the function of the welding head. If bite occurs, try to remove the welding head while the welding pen is still hot. To prevent biting, the welding head can be removed from the welding pen at intervals.